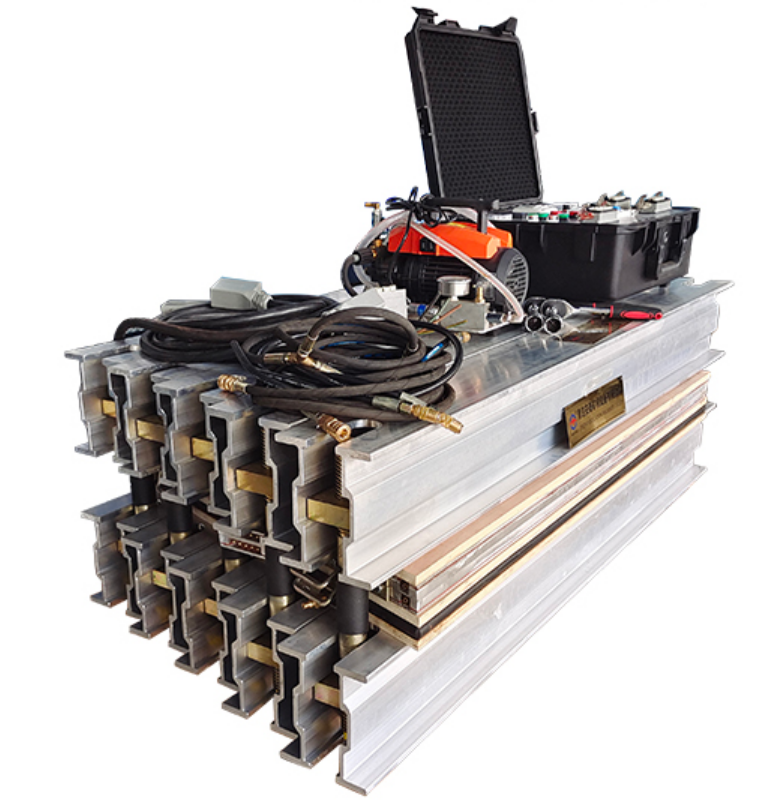

Belt Splice Vulcanizer

The vuclanizer cools down rapidlly saving splicing job time. The temperature raise up fast and uniform across splice area. Pressure is even. Easy for operation and maintenance.

Vulcanizing machine is essential for conveyor belt to achieve high quality splicing and repair.

The vulcanizing machine series products use electric heating combination technology provides uniform heating between hot plates. The high pressure bag has the advantages of uniform pressure, easy operation and reliable quality. The control system uses new automatic digital control box. It is easy to operate, functional stability and light weight. It is suitable for curing joints of fabric, nylon, steel, PVC/PVG and other types of belt. The vulcanizing machine is widely used in steel plant, mining, cement, power plant, port, building materials, chemical and other industries of various transport belt vulcanization joint and repair.

Feature

l Universal to fabric, nylon, steel, PVC/PVG and other types of belt maintenance

l Uniform temperature on heat platen by optimized electricity heating design

l Even pressure conducted by pressure bag with water

l High quality pressure bag offers excellent and stable performance.

l Automatic and quick heating system.

l Temperature limit protection system.

l Operating friendly.

Specification

l Belt Width: 500-2200mm, can be customized as request.

l Heat Platen Length: 250-1020mm, can be customized as request;

l Heat Platen Angle: 17°,22°,90°,can be customized as request;

l Power Supply: 380V, others as request.

l Pressure media: water (standard)

l Cooling method: air or water

Packaging

Export approved plywood box.

Spot repair machine is necessary to conduct small size repair on belt.

Feature

Suitable for regional repair with size less than 300×300mm.

Quick and precise temperature control system.

Stable performance by hydraulic pressing system.

Friendly to use, easy to move.

Temperature Control Box

Electricity insulated, dust & waterproof design.

Automatic control on heating, keeping temperature being constant.

Temperature at 3-5 points of heat plate is detected dynamically.

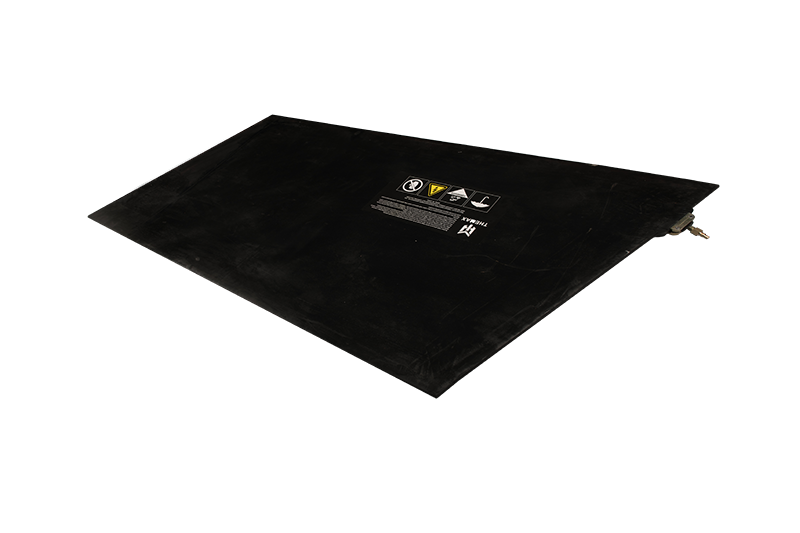

Pressure Bag

Light Weight & High Strength

Uniform Pressure

Heat Platen

Heat platen size and angle as requested.